To achieve a carbon-neutral society by 2050, nuclear energy needs to be utilized long-term. Hitachi GE Vernova Nuclear Energy is developing fast reactor and fuel cycle technologies while working to effectively utilize resources and reduce the environmental impact of radioactive waste, to make nuclear energy an even safer and more sustainable source of fuel that enjoys greater social acceptance.

Uranium is a substance found in natural minerals and sea water, and mainly comprises two types: Uranium 235 (about 0.7% of natural deposits), and Uranium 238 (around 99.3%). Today, enriched uranium, a type whose uraniuim-235 concentration has been increased to 3-5%, is used for fuel, but at this rate the world’s uranium resources will be exhausted in several decades to over a hundred years.

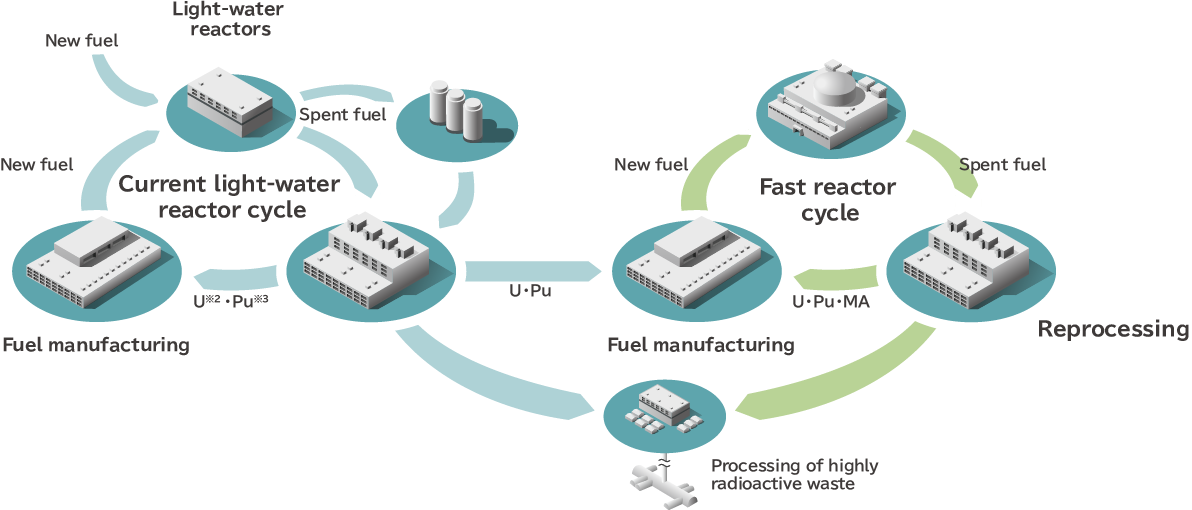

The fast reactor fuel cycle is a fuel reuse plan that seeks to effectively use these uranium resources and dramatically boost usage efficiency. Reusing recovered spent fuel and utilizing previously unutilized Uranium 238 as fuel in “fast reactors” will enable sustainable energy.

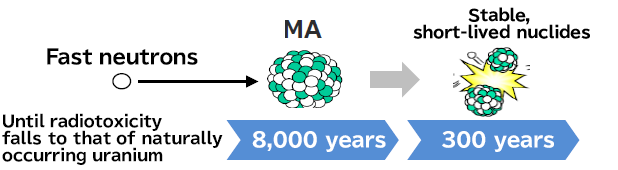

The fuel used at nuclear power plants includes not only the materials that are reusable as resources, but so-called minor actinides that remain radioactive and heat-generating for long periods. Since these highly toxic materials are contained in radioactive waste, it takes around 8000 years to revert to the same radiological dosage as naturally occurring uranium, but by using a fast reactor to perform nuclear transmutation, that time can be shortened to around 300 years.

Through the fuel cycle we envisage, fuel used for nuclear power generation can be reprocessed into what is known as MOX fuel*1 and reused as a fuel for nuclear power generation. After power generation, spent fuel contains non-fissioned uranium and plutonium produced in the reactor. These materials can be extracted and used as fuel for nuclear power generation again. In addition, the fast reactor cycle vastly improves the usage efficiency of resources such as uranium, making it possible to sustainably utilize nuclear energy in the future. The fuel cycle can also reduce the volume of highly toxic radioactive waste and significantly shorten the time taken for the radiation dosage to decline and reach a level of harmfulness comparable to naturally occurring uranium.

Hitachi GE Vernova Nuclear Energy is developing a range of technologies highlighted below to make these nuclear fuel cycle a reality.

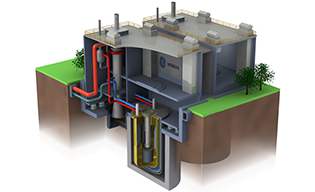

Hitachi GE Vernova Nuclear Energy has participated in the design, construction and maintenance of the Joyo experimental fast reactor and Monju prototype fast breeder reactor. We will continue to contribute to construction work on Joyo for compliance with new regulations and its restarting, and measures for decommissioning of Monju. We are also working on a joint basis with GE Vernova Hitachi Nuclear Energy in the US to develop the PRISM metal fuel fast reactor, which combines economy, safety and flexibility. In the event of an accident, PRISM employs passive safety systems enabling long-term reactor core cooling within the need for a power source or operational control, and also uses metal fuel, which is known for its inherent safety and other qualities. Additionally, a flexible plant configuration with high levels of safety can be achieved based on the number of compact modular reactors installed, each with a capacity of 311 MWe.

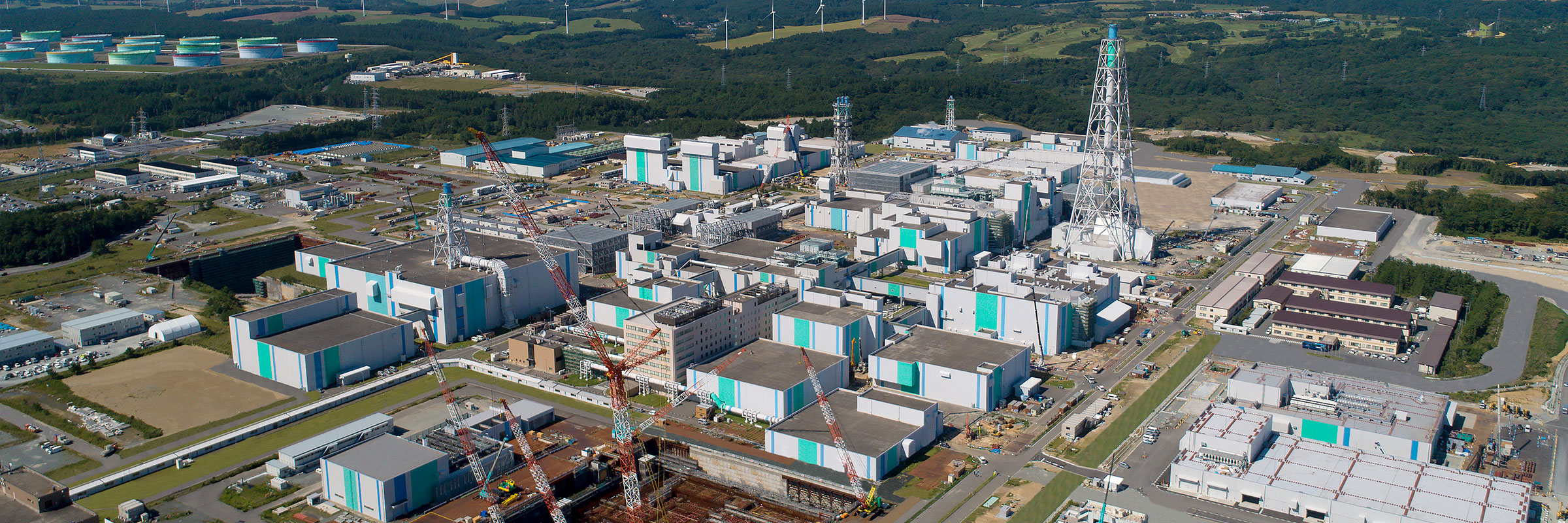

Prototype Fast Breeder Reactor Monju Photos

courtesy of Japan Atomic Energy Agency (JAEA)

Innovative Small Sodium-Cooled Fast Reactor PRISM

The Rokkasho Reprocessing Plant is Japan’s first commercial nuclear fuel cycle facilities, which is under construction by Japan Nuclear Fuel Limited (JNFL). Our products are delivered mainly for the spent fuel receiving and storage building, the separation building, the purification building, the low active liquid waste treatment building, and the control building.

Rokkasho Reprocessing Plant (Source: the Japan Nuclear Fuel Limited (JNFL))

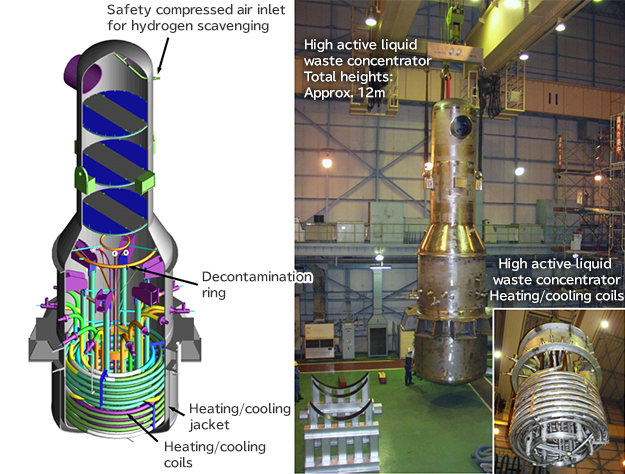

Separation building

High active liquid waste concentrator

A principal device in the separation building, concentrating and reducing volume of the high active effluent generated after separating uranium and plutonium from nitric acid solution containing nuclear spent fuels.

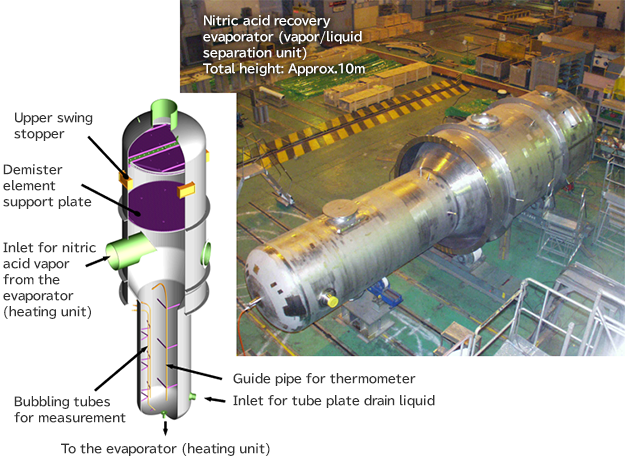

Purification building

Nitric acid recovery evaporator

A principal device in the separation and purification building, recovering nitric acid from nitric acid effluent generated in the reprocessing plant.

The fast reactor cycle is a technology designed to realize a more sustainable society by making effective use of energy resources. The technology secures sustainable energy while using fuel containing minor actinides (MA) to shorten the time taken for radioactive waste to revert to a radiotoxicity level equivalent to naturally occurring uranium to around 300 years. Hitachi GE Vernova Nuclear Energy is pursuing research to establish a fast reactor cycle toward a future that strikes a balance between the sustainable supply of energy and solutions to the waste challenges faced by nuclear energy.