We deliver the equipment for contaminated water measures and pool fuel removal with regard to the decommissioning program, which are specified in the “Mid-to-Long-Term Roadmap towards the Decommissioning of TEPCO's Fukushima Daiichi Nuclear Power Station Units 1-4 (Mid-to-Long-Term Roadmap)“ and “Mid-and-Long-Term Decommissioning Action Plan 2020“*1, to Tokyo Electric Power Company Holdings, Inc. based on the experiences and achievements accumulated as a plant manufacturer.

We are implementing the following activities for research and development on mid- and long-term issues regarding the decommissioning program specified in the “Mid-to-Long-Term Roadmap” and “Mid-and-Long-Term Decommissioning Action Plan 2020.”

We will continue to contribute to decommissioning of Fukushima Daiichi Nuclear Power Station through technological development.

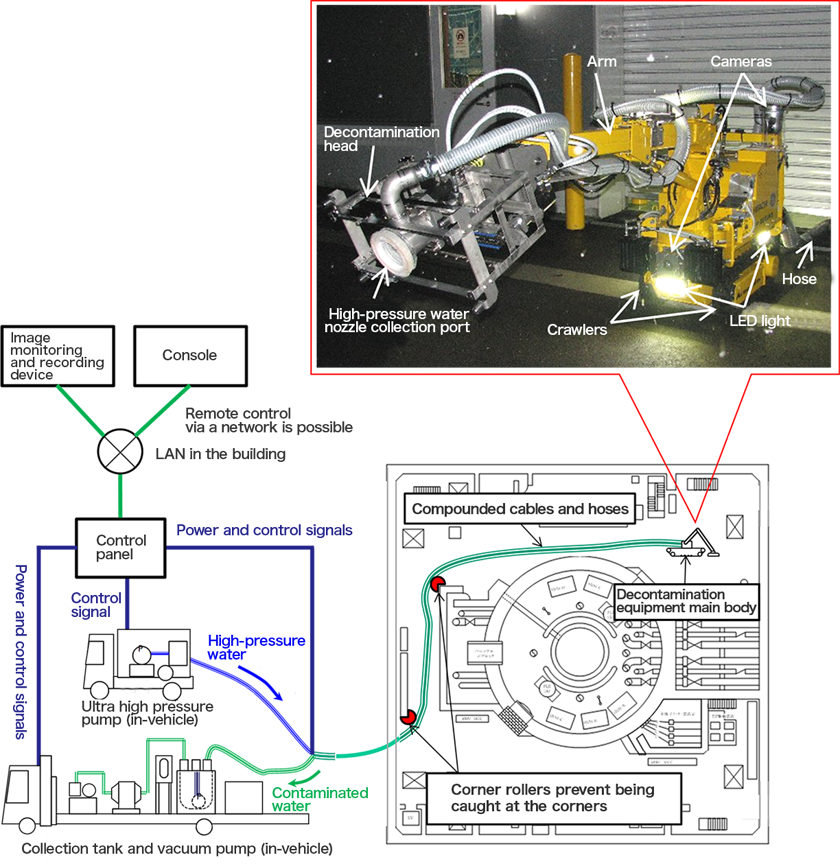

In the “Development of Remote Decontamination Technology in the Reactor Building” project implemented by the Agency for Natural Resources and Energy, we developed Arounder*2, remote decontamination equipment using high-pressure water that improves the radiation-polluted environment at the incident site of Fukushima Daiichi Nuclear Power Station.

Photo 1. Arounder, remote decontamination equipment using high-pressure water

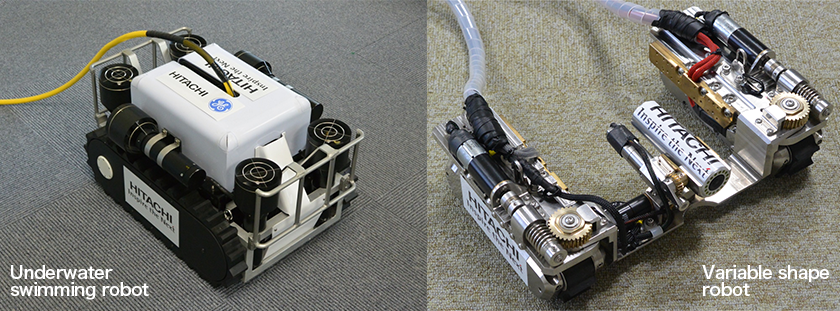

Hitachi and Hitachi GE Vernova Nuclear Energy developed an underwater swimming robot and variable shape robot to be used for a survey to remove fuel at Fukushima Daiichi Nuclear Power Station.

The underwater swimming robot will survey the inside of the power station building that is filled with water and can be used as equipment that surveys retained water leakage locations in the nuclear power station from underwater.

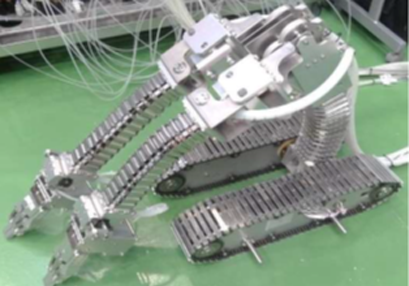

In addition, because the nuclear power station has areas with high radiation dose, openings for inserting the equipment into the targeted section must be as small as possible. However, small-sized moving equipment was unstable and had problems running. This robot has a basic shape of stable moving equipment, combining two small-sized crawlers, and can change its shape to pass through a narrow space.

Photo 2. Submersible crawling and swimming robot(left) and Shape-changing robots (right)

As a member of International Research Institute for Nuclear Decommissioning (IRID) since its establishment, we are conducting research and development and other projects regarding decommissioning and performing the following activities.

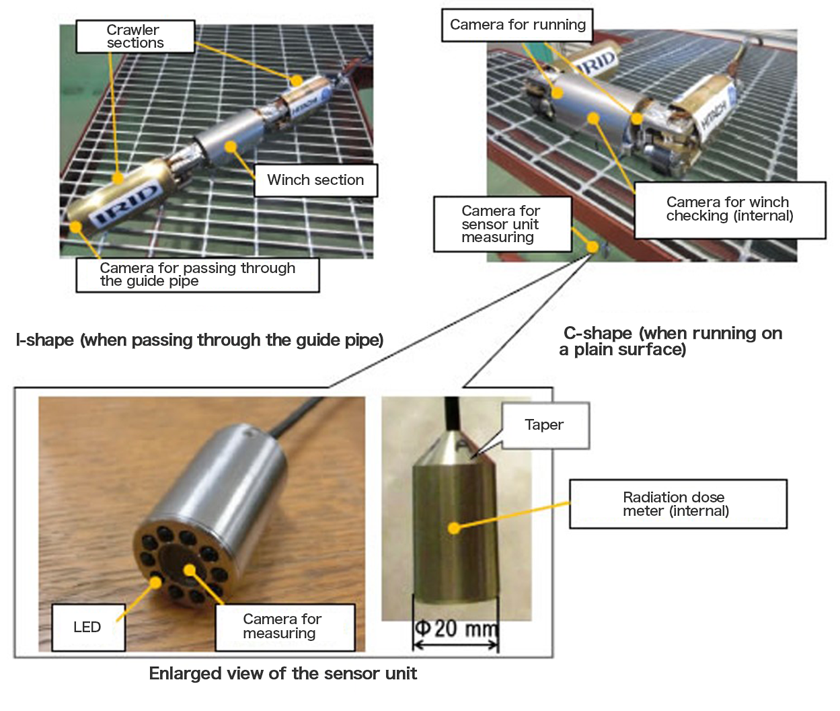

Fukushima Daiichi Nuclear Power Station Units 1, 2, and 3 may have fuel debris inside the primary containment vessel (PCV). To remove it, the internal situation of the PCV must be investigated. We are developing equipment to be used for that investigation.

Photo 3. the PCV (Primary Containment Vessel) internal investigation robot "PMORPH"

Photo 4. The boat-type submersible access devices and small-type remotely operated vehicles, which investigate interiors of PCV

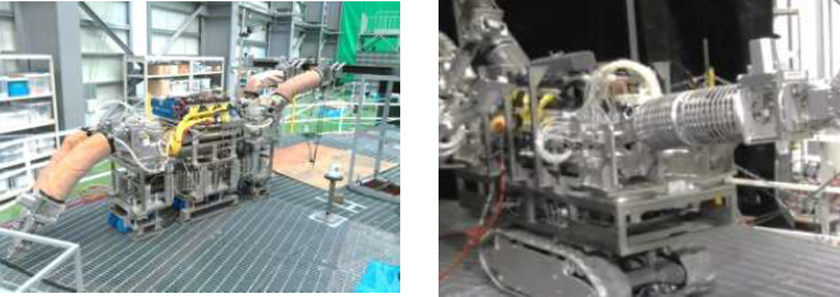

We are researching the application of the remotely operable the Muscle Robot with Flexible Structuring Mechanism that has superior radiation hardness and impact resistance to the fuel debris removal, where work in a high-dose environment is assumed.

Photos 5 and 6. the Muscle Robot with Flexible Structuring Mechanism

(Assumed work: Handling of heavy objects, handing over between adjacent arms, assembly and disassembly)

Photo 7. the Muscle Robot with Flexible Structuring Mechanism

(Assumed work: Establishment of environment for installing cameras and handling cables)

Photo 8. the Muscle Robot with Flexible Structuring Mechanism (Assumed work: Assembly and disassembly)

Photos 9 and 10. the Muscle Robot with Flexible Structuring Mechanism

(Photo 9: Assumed work: Entry into narrow spaces, lifting/lowering in conjunction with a winch, ascending/descending by clinging and lifting of long objects

Photo 10: Assumed work: Work as a replacement for humans, narrow spaces and moving while hanging)

Photo 11. the Muscle Robot with Flexible Structuring Mechanism

(Assumed work: Cable arrangement for the other robots and work in a narrow space)