Digitization is underway in many businesses including the nuclear power business.

We are working to improve reliability through the enhancement of equipment reliability, digitization of monitoring and diagnosing services, and improvement of operators’ skills, among other initiatives.

Here are some of the ongoing initiatives.

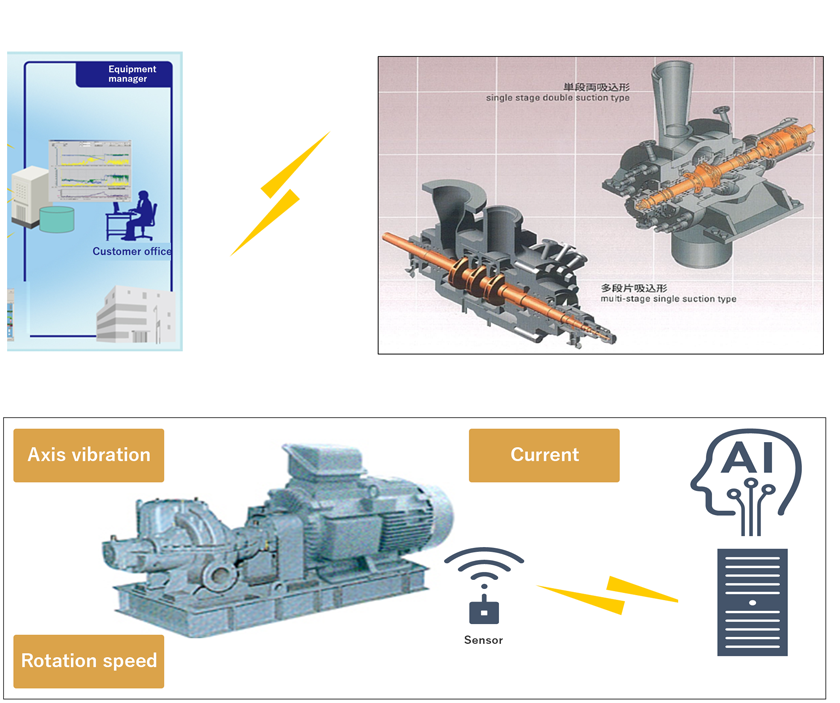

We provide technologies that enable operators to remotely monitor and diagnose pumps installed at nuclear power plants.

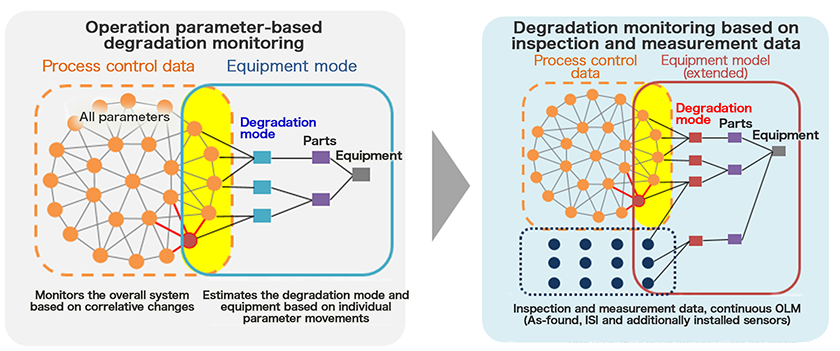

We provide an algorithm that analyzes operation parameter-based degradation according to process control data and equipment models.

Based on that analysis, we provide a degradation diagnosing service with respect to equipment that implements the monitoring of degradation through inspection and measurement data.

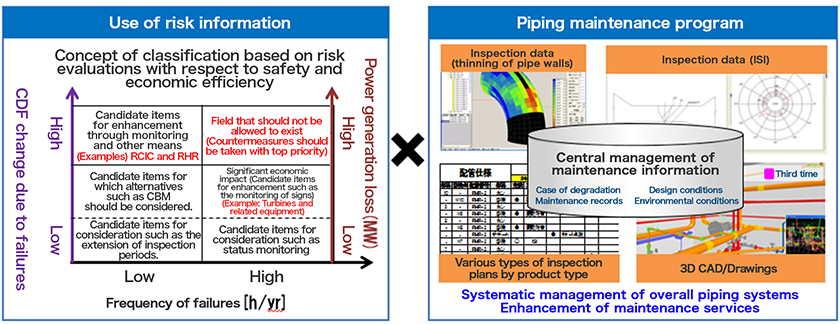

We increase the stability of nuclear power plants by leveraging synergy effects using risk information and implementation of maintenance programs.

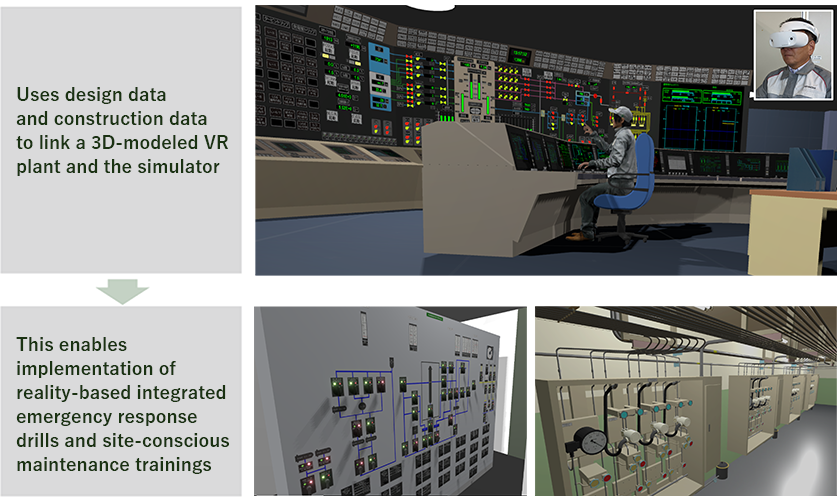

The efficiency of on-site operations has been declining mainly due to aging operators and a lack of experience.

There is an urgent need to improve efficiency through the education and training of field operators and preparation of operation manuals, among other initiatives.

We are working to establish the education and training system that integrates these needs .

Initially, we facilitate these initiatives within the Hitachi Group.

Subsequently, we collaborate with electric power companies and share the education and training system and other initiatives.