We are working to develop radioactive waste processing technologies and decommissioning technologies at nuclear facilities based on our track record in the construction of these facilities and in regular inspections and maintenance work at plants in operation. With a focus on radioactive waste processing, measurement of radioactivity, chemical decontamination and cutting from among our radioactive waste disposal and decommissioning technologies for nuclear power generation facilities, the following outlines individual technological areas and presents their respective features and progress in development.

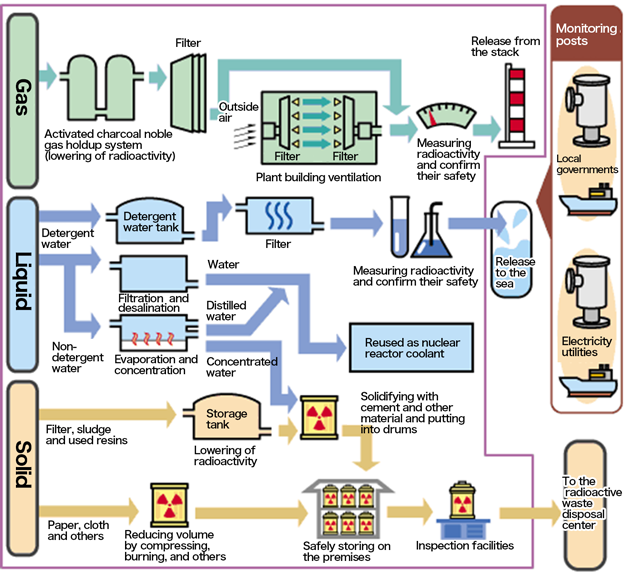

Radioactive waste is generated from the operation of nuclear power plants. They are categorized into gas, liquid and solid. Radioactive waste is disposed properly and safely.

For noble gas from the turbine system and other gas waste, radioactivity is sufficiently lowered with the decay system (Hold-up System) and/or filtration. While the safety of the waste is being checked, it is released through a stack with the dilution for releasing into the atmosphere.

For the liquid waste generated from equipment, detergent water waste and other liquid waste, radioactive substances, suspension solid, organic substances and others are removed by filtration, evaporation and demineralization. it is either reused in the power plant or is released into the sea with the sufficient dilution after the safety is fully checked.

For solid radioactive waste, concentrated waste fluid and miscellaneous solid with relatively low radioactivity levels are solidified with cement or mortar into the 200L drums. They are transported to the Low-Level Radioactive Waste Disposal Center of Japan Nuclear Fuel Limited (JNFL) and finally disposed in this facility. Waste with relatively high radioactivity will be solidified with cement after the radioactivity is properly decayed.

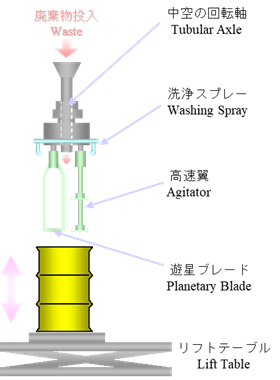

With respect to radioactive waste generated from power plants, we are developing diverse technologies for increasing reliability and economic efficiency in accordance with a basic policy of reducing the quantity generated from sources, safely storing it after generation and solidification treatment. Concentrated liquid waste and spent ion exchange resins are uniformly solidified using cement and other materials. Our in-drum cement mixing and solidification system features a simple configuration, a high filling rate and reuse of cleaning water for reducing secondary waste. It solidifies actual radioactive waste.

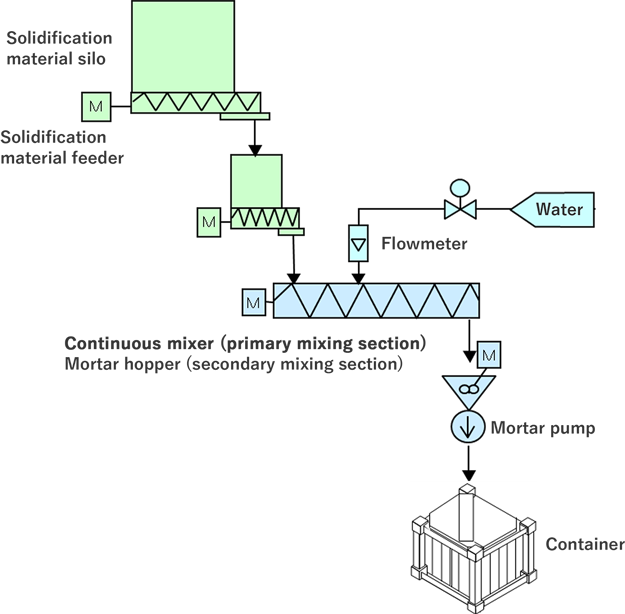

To solidify non-combustible, miscellaneous solid waste generated from maintenance and other processes at nuclear plants, cement or mortar is injected through a gap opening into a drum filled with properly sorted and volume-reduced waste. The continuous mortar filling and solidification system is compact and designed to continuously mix water and solidifying materials. It was delivered to several power plants to solidify actual radioactive waste. Unlike the batch system, there is no limit to the mixing amount per use, making it suitable to meet the needs of a higher waste processing capacity for large demolition waste processing during decommissioning.

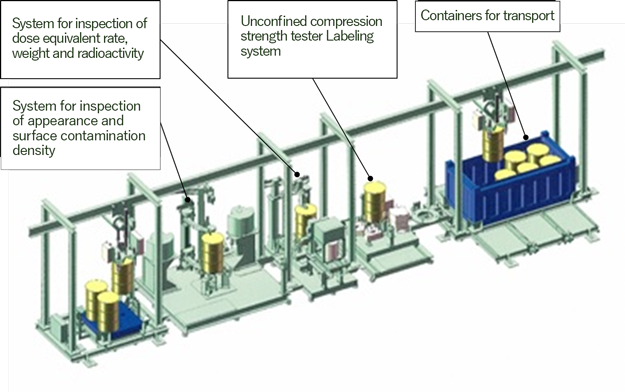

Low-level radioactive solid waste generated at nuclear plants is solidified in drums using cement and other solidifying materials. They shall be checked before transporting to the final disposal site*1 if they meet the acceptance criteria for the final disposal site. Low-level radioactive waste solidified package inspection system is used for the inspection. A series of inspections on appearance, weight, surface contamination density, dose equivalent rate and radioactive concentration are measured and checked automatically. The 200L drums waste package that meet the acceptance criteria are placed into a container for transport. We have delivered the system to several nuclear sites, with a track record of operation of around 30 years.

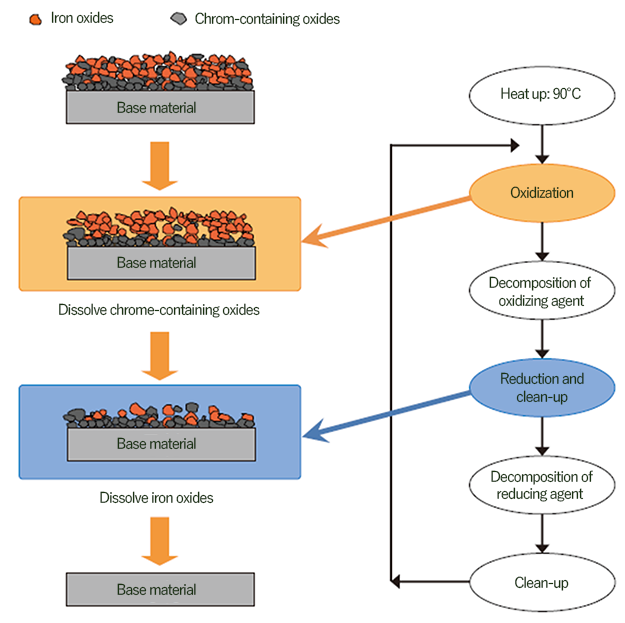

Our chemical decontamination technique called HOP (Hydrazine, Oxalic Acid, Potassium Permanganate) method was originally developed to reduce occupational exposure at plants in operation. With this method, we have performed a great number of chemical decontaminations mainly on high dose piping and components in Japan and overseas. It is also applicable to large volume, high-dose structures such as reactor pressure vessels and has been employed at a plant undergoing decommissioning. We will continue to develop techniques that meet a variety of needs concerning decommissioning and expand their application in the global decommissioning market.

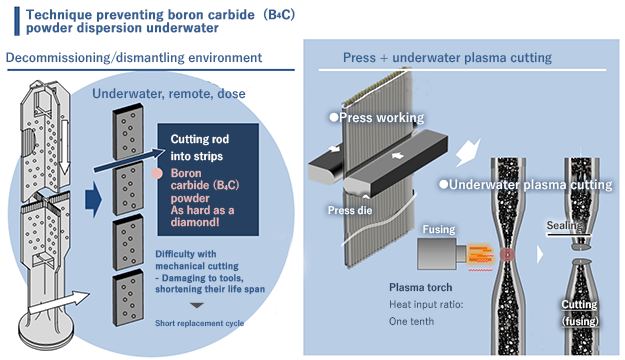

Used control rods are subject to intermediate depth disposal and will be buried. A single control rod has an approximate length of 4 meters. However, it must be cut so that it can be stored in an intermediate depth disposal vessel. After cutting the rod, the boron carbide (B4C) powder inside the rod is scattered into water, resulting in spreading contamination and increasing the burden of secondary treatment. To prevent the content of the rod from being scattered with the used control rod cutting system, we are developing a cutting technology that combines press working and underwater plasma cutting.